NEW

What is the Mainstream Shanghai Resistor Production Process?

I. Introduction

Resistors are fundamental components in electronic circuits, serving the critical function of controlling the flow of electric current. They are essential for regulating voltage, dividing signals, and protecting sensitive components from excessive current. As the demand for electronic devices continues to rise globally, the production of resistors has become increasingly significant. Shanghai, a major hub for electronics manufacturing, plays a pivotal role in the global resistor market. This article aims to explore the mainstream resistor production process in Shanghai, shedding light on the intricacies involved in creating these vital components.

II. Understanding Resistors

A. Definition and Function of Resistors

A resistor is a passive electrical component that provides resistance to the flow of electric current. The primary function of a resistor is to limit current, divide voltages, and dissipate energy in the form of heat. Resistors are characterized by their resistance value, which is measured in ohms (Ω).

B. Types of Resistors Commonly Produced

1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in various applications, from simple circuits to complex electronic devices.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow for adjustable resistance, making them ideal for applications like volume controls in audio equipment.

3. **Specialty Resistors**: This category includes precision resistors, high-power resistors, and temperature-sensitive resistors, which are designed for specific applications and performance requirements.

C. Applications of Resistors in Various Industries

Resistors find applications across multiple industries, including consumer electronics, automotive, telecommunications, and industrial automation. They are integral to devices such as smartphones, computers, and medical equipment, where precise control of electrical signals is crucial.

III. The Resistor Production Process

A. Overview of the Production Workflow

The production of resistors involves a series of well-defined stages, each critical to ensuring the quality and performance of the final product. The process begins with material selection and culminates in packaging and distribution.

B. Key Stages in the Resistor Manufacturing Process

1. **Material Selection**

- **Types of Materials Used**: The choice of materials is paramount in resistor production. Common materials include carbon, metal film, and wire wound elements. Each material offers distinct characteristics, such as stability, temperature coefficient, and power handling capabilities.

- **Quality Control Measures for Raw Materials**: Rigorous quality control is implemented to ensure that raw materials meet industry standards. This includes testing for purity, consistency, and performance characteristics.

2. **Component Fabrication**

- **Techniques for Creating Resistor Elements**: Various fabrication techniques are employed, including screen printing for thick film resistors and deposition methods for thin film resistors. Each technique requires precision to achieve the desired resistance values.

- **Importance of Precision in Fabrication**: The accuracy of the fabrication process directly impacts the performance of the resistor. Tolerances must be tightly controlled to ensure reliability in electronic applications.

3. **Assembly**

- **Methods of Assembling Resistor Components**: After fabrication, resistor components are assembled into their final form. This may involve soldering leads, encapsulating elements, or integrating them into circuit boards.

- **Use of Automated vs. Manual Assembly Processes**: While some assembly processes are automated to enhance efficiency, manual assembly is still prevalent for specialty resistors that require careful handling.

4. **Testing and Quality Assurance**

- **Types of Tests Conducted**: Comprehensive testing is conducted to verify the electrical, thermal, and mechanical properties of resistors. This includes measuring resistance values, temperature coefficients, and power ratings.

- **Standards and Certifications**: Compliance with international standards such as ISO and RoHS is essential. These certifications ensure that resistors meet safety and environmental regulations.

5. **Packaging and Distribution**

- **Packaging Methods to Ensure Product Integrity**: Proper packaging is crucial to protect resistors from damage during transportation. Anti-static materials and moisture-resistant packaging are commonly used.

- **Logistics and Distribution Channels**: Efficient logistics and distribution networks are vital for delivering resistors to customers worldwide. Shanghai's strategic location and advanced infrastructure facilitate this process.

IV. Technological Innovations in Resistor Production

A. Advances in Materials Science

Recent advancements in materials science have led to the development of new resistor materials that offer improved performance and reliability. For instance, the use of nanomaterials has enhanced the thermal stability and precision of resistors.

B. Automation and Robotics in Manufacturing

The integration of automation and robotics in resistor production has significantly increased efficiency and reduced labor costs. Automated systems can perform repetitive tasks with high precision, minimizing human error.

C. Impact of Industry 4.0 on Resistor Production

Industry 4.0 technologies, such as the Internet of Things (IoT) and big data analytics, are transforming resistor manufacturing. These technologies enable real-time monitoring of production processes, leading to improved quality control and predictive maintenance.

D. Sustainability Practices in Resistor Manufacturing

Sustainability is becoming increasingly important in resistor production. Manufacturers in Shanghai are adopting eco-friendly practices, such as reducing waste, recycling materials, and minimizing energy consumption.

V. Challenges in the Resistor Production Process

A. Supply Chain Issues and Material Shortages

The global semiconductor shortage has impacted the availability of raw materials for resistor production. Manufacturers must navigate these challenges to maintain production levels and meet customer demand.

B. Competition in the Global Market

Shanghai faces intense competition from other manufacturing hubs, particularly in Asia. To remain competitive, local manufacturers must focus on innovation, quality, and cost-effectiveness.

C. Regulatory Challenges and Compliance

Navigating the complex landscape of international regulations can be challenging for resistor manufacturers. Compliance with various standards requires ongoing investment in quality assurance and testing.

D. Environmental Concerns and Waste Management

As environmental regulations become stricter, manufacturers must implement effective waste management practices. This includes reducing hazardous waste and ensuring proper disposal of materials.

VI. The Future of Resistor Production in Shanghai

A. Trends Shaping the Future of Resistor Manufacturing

The future of resistor production in Shanghai will be influenced by trends such as miniaturization, increased demand for high-performance components, and the rise of electric vehicles.

B. Potential for Growth and Innovation in Shanghai

Shanghai's robust manufacturing ecosystem, coupled with its focus on research and development, positions it well for growth in the resistor market. Continued investment in innovation will drive advancements in production techniques.

C. Role of Research and Development in Advancing Production Techniques

Research and development will play a crucial role in enhancing resistor production processes. Collaborations between manufacturers and academic institutions can lead to breakthroughs in materials and manufacturing technologies.

VII. Conclusion

The resistor production process is a complex and multifaceted endeavor that requires precision, quality control, and innovation. Shanghai's prominence in the global resistor market underscores its importance as a manufacturing hub. As the electronics industry continues to evolve, the future of resistor manufacturing in Shanghai looks promising, with opportunities for growth and advancements in technology. The ongoing commitment to quality and sustainability will ensure that Shanghai remains a key player in the global resistor landscape.

VIII. References

A comprehensive list of sources and further reading materials on resistor production and manufacturing processes would typically follow here, providing readers with additional insights and information on the topic.

What are the Popular Models of Resistors for Their Role in Circuits?

I. Introduction

Resistors are fundamental components in electrical circuits, serving as the building blocks for a wide range of applications. They are passive devices that limit the flow of electric current, making them essential for controlling voltage and current levels in various electronic devices. Understanding the different types of resistors and their specific roles in circuits is crucial for anyone involved in electronics, whether you're a hobbyist, student, or professional engineer. This article will explore the popular models of resistors, their characteristics, applications, and the factors influencing their selection in circuit design.

II. Understanding Resistors

A. Basic Functionality of Resistors

At the core of a resistor's functionality is Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship is expressed mathematically as:

\[ V = I \times R \]

This fundamental principle allows resistors to control the flow of current in a circuit, making them indispensable in various applications.

B. Types of Resistors

Resistors can be broadly categorized into three types: fixed resistors, variable resistors, and special resistors. Each type serves different purposes and is designed to meet specific requirements in electronic circuits.

1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in circuits where a specific resistance is required.

2. **Variable Resistors**: These allow for adjustable resistance values, making them suitable for applications where fine-tuning is necessary.

3. **Special Resistors**: These include resistors designed for specific functions, such as temperature sensing or light detection.

III. Popular Models of Resistors

A. Fixed Resistors

Fixed resistors are the most common type used in electronic circuits. Here are some popular models:

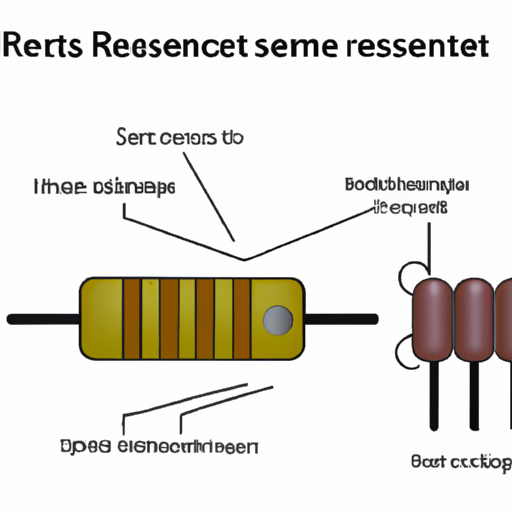

1. Carbon Composition Resistors

**Characteristics**: Made from a mixture of carbon and a binding material, carbon composition resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a relatively high tolerance and are less stable over time compared to other types.

**Applications**: These resistors are often used in applications where high energy pulses are expected, such as in power supplies and audio equipment.

2. Metal Film Resistors

**Characteristics**: Metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer better stability, lower noise, and tighter tolerances than carbon composition resistors.

**Applications**: Commonly used in precision applications, such as in measurement devices and high-frequency circuits, metal film resistors are favored for their reliability.

3. Wirewound Resistors

**Characteristics**: Wirewound resistors are constructed by winding a metal wire around a ceramic or fiberglass core. They can handle high power levels and have low resistance values.

**Applications**: These resistors are typically used in power applications, such as in power supplies and motor control circuits, where high power dissipation is required.

4. Thick and Thin Film Resistors

**Characteristics**: Thick film resistors are made by printing a resistive paste onto a substrate, while thin film resistors are created by depositing a thin layer of resistive material. Thin film resistors offer better precision and stability.

**Applications**: Thick film resistors are often used in general-purpose applications, while thin film resistors are preferred in high-precision applications, such as in instrumentation and medical devices.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits.

1. Potentiometers

**Characteristics**: Potentiometers consist of a resistive element and a movable contact (wiper) that adjusts the resistance. They can be used as voltage dividers.

**Applications**: Commonly found in volume controls, tone controls, and other user-adjustable settings in audio equipment and consumer electronics.

2. Rheostats

**Characteristics**: Rheostats are a type of variable resistor designed to handle higher currents. They typically have two terminals and are used to adjust current flow.

**Applications**: Often used in applications such as dimmer switches for lights and motor speed controls, rheostats provide a simple way to control power levels.

C. Special Resistors

Special resistors are designed for specific applications, often involving unique characteristics.

1. Thermistors

**Characteristics**: Thermistors are temperature-sensitive resistors that exhibit a significant change in resistance with temperature variations. They can be either NTC (Negative Temperature Coefficient) or PTC (Positive Temperature Coefficient).

**Applications**: Commonly used in temperature sensing and control applications, such as in thermostats and temperature compensation circuits.

2. Photoresistors

**Characteristics**: Also known as LDRs (Light Dependent Resistors), photoresistors change their resistance based on the amount of light falling on them. They have high resistance in darkness and low resistance in light.

**Applications**: Used in light-sensing applications, such as automatic streetlights, camera exposure controls, and light meters.

3. Varistors

**Characteristics**: Varistors are voltage-dependent resistors that change their resistance based on the applied voltage. They are designed to protect circuits from voltage spikes.

**Applications**: Commonly used in surge protection devices and voltage clamping applications to safeguard sensitive electronic components.

IV. Applications of Resistors in Circuits

Resistors play a crucial role in various applications within electronic circuits:

A. Current Limiting

Resistors are often used to limit the current flowing through a circuit, protecting sensitive components from damage due to excessive current.

B. Voltage Division

By using resistors in series, voltage dividers can be created to obtain a specific voltage level from a higher voltage source, which is essential in many applications.

C. Signal Conditioning

Resistors are used in signal conditioning circuits to filter, amplify, or modify signals, ensuring that they meet the required specifications for further processing.

D. Biasing Active Devices

In amplifier circuits, resistors are used to set the biasing conditions for transistors and operational amplifiers, ensuring they operate in the desired region of their characteristics.

E. Pull-up and Pull-down Resistors

In digital circuits, pull-up and pull-down resistors are used to ensure that inputs to logic gates are at defined logic levels when no active devices are driving the inputs.

V. Factors Influencing Resistor Selection

When selecting a resistor for a specific application, several factors must be considered:

A. Resistance Value

The resistance value must match the requirements of the circuit to ensure proper functionality.

B. Power Rating

Resistors have a maximum power rating, and selecting a resistor with an appropriate power rating is crucial to prevent overheating and failure.

C. Tolerance

Tolerance indicates the precision of the resistor's value. In applications requiring high accuracy, low-tolerance resistors are preferred.

D. Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. This is important in applications where temperature variations are expected.

E. Size and Form Factor

The physical size and form factor of the resistor must fit within the design constraints of the circuit, especially in compact electronic devices.

VI. Conclusion

In summary, resistors are vital components in electronic circuits, serving various roles from current limiting to signal conditioning. Understanding the different types of resistors, their characteristics, and applications is essential for effective circuit design. As technology advances, the role of resistors in modern electronics continues to evolve, with trends toward miniaturization, improved precision, and enhanced performance. By staying informed about resistor technology, engineers and hobbyists alike can make better choices in their electronic designs.

VII. References

A. Suggested Reading

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronic Principles" by Albert Malvino and David Bates

B. Relevant Standards and Guidelines

- IEC 60115: Resistors for use in electronic equipment

- EIA-198: Standard for Fixed Resistors

C. Online Resources for Further Learning

- Electronics tutorials on websites like All About Circuits and Electronics-Tutorials.ws

- Online courses on platforms like Coursera and edX focusing on electronics and circuit design.

This comprehensive exploration of resistors and their roles in circuits provides a solid foundation for understanding their importance in electronics. Whether you're designing a simple circuit or a complex system, the knowledge of resistors will undoubtedly enhance your capabilities as an engineer or hobbyist.

What is the Mainstream Current Sensing Resistor Production Process?

I. Introduction

A. Definition of Current Sensing Resistors

Current sensing resistors, often referred to as shunt resistors, are specialized components used in electronic circuits to measure the flow of electric current. They operate on the principle of Ohm's law, where the voltage drop across the resistor is proportional to the current flowing through it. By measuring this voltage drop, engineers can accurately determine the current in a circuit, making these resistors essential for various applications, including power management, battery monitoring, and motor control.

B. Importance of Current Sensing Resistors in Electronic Circuits

In modern electronics, the ability to monitor current is crucial for ensuring the efficiency and safety of devices. Current sensing resistors play a vital role in protecting circuits from overcurrent conditions, optimizing power consumption, and enabling feedback mechanisms in control systems. Their applications span across industries, from consumer electronics to automotive and industrial automation, highlighting their significance in contemporary technology.

C. Overview of the Production Process

The production of current sensing resistors involves a series of intricate steps, from design and material selection to fabrication and testing. Understanding this process is essential for manufacturers and engineers alike, as it impacts the performance, reliability, and cost-effectiveness of the final product.

II. Types of Current Sensing Resistors

A. Shunt Resistors

1. Characteristics

Shunt resistors are typically low-resistance components designed to handle high currents. They are characterized by their ability to provide accurate current measurements with minimal impact on the circuit's performance.

2. Applications

Commonly used in power supplies, battery management systems, and motor drives, shunt resistors are integral to applications requiring precise current monitoring.

B. Wirewound Resistors

1. Characteristics

Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. They offer high precision and stability, making them suitable for high-power applications.

2. Applications

These resistors are often found in power amplifiers, industrial equipment, and high-current applications where durability and reliability are paramount.

C. Thin Film Resistors

1. Characteristics

Thin film resistors are created by depositing a thin layer of resistive material onto a substrate. They provide excellent accuracy, low temperature coefficient, and high stability.

2. Applications

Thin film resistors are commonly used in precision measurement devices, medical equipment, and aerospace applications where performance is critical.

D. Thick Film Resistors

1. Characteristics

Thick film resistors are produced by screen printing a thick layer of resistive paste onto a substrate. They are cost-effective and can be manufactured in various shapes and sizes.

2. Applications

These resistors are widely used in consumer electronics, automotive applications, and general-purpose circuits due to their versatility and affordability.

III. Materials Used in Current Sensing Resistor Production

A. Base Materials

1. Metal Alloys

Metal alloys, such as nickel-chromium and manganin, are commonly used for their stable resistance characteristics and low temperature coefficients. These materials ensure accurate current sensing across a range of temperatures.

2. Carbon Composites

Carbon composites are also utilized for their high thermal stability and low cost. They are particularly effective in applications where weight is a concern.

B. Substrates

1. Ceramic

Ceramic substrates are favored for their excellent thermal conductivity and electrical insulation properties. They provide a stable base for high-performance resistors.

2. Epoxy

Epoxy substrates are often used in thick film resistors due to their flexibility and ease of processing. They are suitable for applications requiring lightweight and compact designs.

C. Coatings and Finishes

1. Protective Coatings

Protective coatings are applied to resistors to enhance their durability and resistance to environmental factors such as moisture and corrosion.

2. Conductive Coatings

Conductive coatings are used to improve the electrical performance of resistors, ensuring reliable current sensing in various conditions.

IV. The Production Process

A. Design and Prototyping

1. Electrical Specifications

The production process begins with defining the electrical specifications, including resistance value, power rating, and tolerance. Engineers use simulation tools to optimize the design for performance.

2. Mechanical Design

Mechanical design considerations, such as size, shape, and mounting options, are also crucial. Prototyping allows for testing and refinement before mass production.

B. Material Preparation

1. Sourcing Raw Materials

Manufacturers source high-quality raw materials, including metal alloys and substrates, from reliable suppliers to ensure consistency and performance.

2. Material Treatment

Raw materials undergo treatment processes, such as annealing or surface preparation, to enhance their properties and ensure optimal performance in the final product.

C. Fabrication Techniques

1. Cutting and Shaping

Materials are cut and shaped according to the design specifications. Precision cutting techniques, such as laser cutting or CNC machining, are employed to achieve the desired dimensions.

2. Layering and Bonding

For thin and thick film resistors, layering and bonding techniques are used to create the resistive element. This may involve screen printing or sputtering processes to deposit the resistive material onto the substrate.

3. Printing Techniques (Thin and Thick Film)

Thin film resistors utilize vacuum deposition methods, while thick film resistors rely on screen printing techniques. Both methods require careful control of parameters to ensure uniformity and accuracy.

D. Assembly

1. Component Integration

Once the resistive elements are fabricated, they are integrated with other components, such as terminals and protective casings, to form the final product.

2. Soldering and Connections

Soldering techniques are employed to create reliable electrical connections. Automated soldering processes are often used to enhance efficiency and consistency.

E. Testing and Quality Control

1. Electrical Testing

Each resistor undergoes rigorous electrical testing to verify its performance against specified parameters. This includes measuring resistance, power rating, and temperature coefficient.

2. Environmental Testing

Environmental testing ensures that resistors can withstand various conditions, such as humidity, temperature fluctuations, and mechanical stress.

3. Reliability Testing

Reliability testing assesses the long-term performance of resistors under continuous operation, ensuring they meet industry standards and customer expectations.

V. Challenges in Current Sensing Resistor Production

A. Precision and Tolerance Issues

Achieving high precision and tight tolerances is critical in current sensing resistor production. Variations in manufacturing processes can lead to discrepancies in performance, necessitating stringent quality control measures.

B. Thermal Management

Thermal management is a significant challenge, as resistors generate heat during operation. Effective thermal design is essential to prevent overheating and ensure reliable performance.

C. Cost Management

Balancing performance and cost is a constant challenge for manufacturers. The choice of materials and production techniques directly impacts the overall cost of the resistors.

D. Environmental Regulations

Manufacturers must comply with environmental regulations regarding materials and waste management. This includes adhering to standards such as RoHS (Restriction of Hazardous Substances) to minimize environmental impact.

VI. Innovations and Future Trends

A. Advances in Materials Science

Ongoing research in materials science is leading to the development of new materials with enhanced properties, such as higher thermal conductivity and lower resistance values, improving the performance of current sensing resistors.

B. Miniaturization and Integration

As electronic devices become smaller and more complex, there is a growing demand for miniaturized current sensing resistors. Innovations in fabrication techniques are enabling the integration of resistors into compact designs.

C. Smart Resistors and IoT Applications

The rise of the Internet of Things (IoT) is driving the development of smart resistors capable of providing real-time data and diagnostics. These advanced components can enhance system performance and enable predictive maintenance.

D. Sustainability in Production

Sustainability is becoming a key focus in resistor production. Manufacturers are exploring eco-friendly materials and processes to reduce their environmental footprint and meet consumer demand for sustainable products.

VII. Conclusion

A. Recap of the Importance of Current Sensing Resistors

Current sensing resistors are indispensable components in modern electronic circuits, enabling accurate current measurement and enhancing the performance of various applications.

B. Summary of the Production Process

The production process of current sensing resistors involves multiple stages, including design, material preparation, fabrication, assembly, and rigorous testing. Each step is crucial for ensuring the quality and reliability of the final product.

C. Future Outlook for Current Sensing Resistor Technology

As technology continues to evolve, the demand for advanced current sensing resistors will grow. Innovations in materials, miniaturization, and smart technologies will shape the future of this essential component, driving improvements in efficiency and performance across a wide range of applications.

VIII. References

A. Academic Journals

- Journal of Electronic Materials

- IEEE Transactions on Components, Packaging and Manufacturing Technology

B. Industry Reports

- Market Research Reports on Resistor Technologies

- Industry Analysis Reports on Electronic Components

C. Manufacturer Specifications

- Datasheets from leading resistor manufacturers

- Technical specifications from component suppliers

D. Online Resources and Articles

- Electronics tutorials and educational websites

- Industry blogs and forums discussing current sensing technologies

This comprehensive overview of the mainstream current sensing resistor production process highlights the importance of these components in modern electronics and the intricate steps involved in their manufacturing. As technology advances, the future of current sensing resistors looks promising, with innovations poised to enhance their performance and applications.

What are the Popular Resistor Standard Product Types?

I. Introduction

A. Definition of Resistors

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are essential for controlling voltage and current levels, ensuring that electronic devices operate safely and effectively. By providing resistance, these components help to manage power distribution, protect sensitive components, and enable various functionalities in electronic circuits.

B. Importance of Resistors in Electronic Circuits

In the realm of electronics, resistors play a crucial role. They are used in a wide array of applications, from simple circuits to complex systems. Resistors help to set biasing conditions for transistors, divide voltages, and filter signals. Without resistors, many electronic devices would not function correctly, leading to potential damage or failure.

C. Overview of Resistor Standard Product Types

Resistors come in various types, each designed for specific applications and requirements. This blog post will explore the popular standard product types of resistors, their specifications, applications, and the latest trends in resistor technology.

II. Types of Resistors

A. Fixed Resistors

Fixed resistors have a constant resistance value and are the most commonly used type in electronic circuits. They come in several subtypes:

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and ability to withstand high temperatures. However, they have a relatively high tolerance and are less stable over time.

2. **Carbon Film Resistors**: These resistors are made by depositing a thin layer of carbon on a ceramic substrate. They offer better stability and lower noise compared to carbon composition resistors, making them suitable for audio applications.

3. **Metal Film Resistors**: Constructed from a thin film of metal, these resistors provide excellent accuracy and stability. They are commonly used in precision applications due to their low temperature coefficient and tight tolerance.

4. **Wirewound Resistors**: Made by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in power applications. They are known for their durability and reliability.

5. **Thin Film Resistors**: Similar to metal film resistors, thin film resistors are made by depositing a thin layer of conductive material. They offer high precision and low noise, making them ideal for high-frequency applications.

6. **Thick Film Resistors**: These resistors are made by printing a thick layer of resistive material onto a substrate. They are widely used in surface mount technology (SMT) due to their compact size and cost-effectiveness.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits. The main types include:

1. **Potentiometers**: These are three-terminal devices used to adjust voltage levels. They are commonly found in volume controls, tone controls, and other applications where variable resistance is needed.

2. **Rheostats**: A type of variable resistor, rheostats are used to control current flow in a circuit. They typically have two terminals and are often used in applications requiring high power.

3. **Trimmers**: Trimmer resistors are small variable resistors used for fine-tuning circuits. They are often used in calibration and adjustment applications, allowing for precise control over resistance.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

1. **Thermistors**: These temperature-sensitive resistors change resistance with temperature variations. They are commonly used in temperature sensing and control applications.

2. **Photoresistors (LDRs)**: Light-dependent resistors change resistance based on light intensity. They are often used in light-sensing applications, such as automatic lighting systems.

3. **Varistors**: Voltage-dependent resistors protect circuits from voltage spikes by changing resistance with voltage levels. They are commonly used in surge protection devices.

4. **Fusible Resistors**: These resistors are designed to act as a fuse, breaking the circuit when a certain current level is exceeded. They provide both resistance and protection in one component.

III. Key Specifications and Ratings

When selecting resistors, several key specifications and ratings must be considered:

A. Resistance Value

The resistance value, measured in ohms (Ω), determines how much current will flow through the resistor at a given voltage. It is crucial to choose the correct resistance value for the intended application.

B. Power Rating

The power rating indicates the maximum power the resistor can dissipate without overheating. It is essential to select a resistor with an appropriate power rating to prevent damage.

C. Tolerance

Tolerance refers to the allowable deviation from the specified resistance value. It is expressed as a percentage and indicates the precision of the resistor. Lower tolerance values are preferred for precision applications.

D. Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. A low temperature coefficient is desirable for applications requiring stability across varying temperatures.

E. Voltage Rating

The voltage rating specifies the maximum voltage that can be applied across the resistor without causing breakdown. It is important to ensure that the voltage rating exceeds the operating voltage in the circuit.

IV. Applications of Different Resistor Types

Resistors are used in a wide range of applications across various industries:

A. Consumer Electronics

In consumer electronics, resistors are used in devices such as televisions, radios, and smartphones. They help control audio levels, manage power distribution, and ensure signal integrity.

B. Automotive Applications

In the automotive industry, resistors are used in various systems, including engine control units, lighting systems, and infotainment systems. They play a vital role in ensuring the reliability and safety of automotive electronics.

C. Industrial Equipment

Industrial equipment relies on resistors for controlling motors, sensors, and other components. They are essential for maintaining operational efficiency and safety in manufacturing processes.

D. Telecommunications

In telecommunications, resistors are used in signal processing, filtering, and impedance matching. They help ensure clear communication and reliable data transmission.

E. Medical Devices

Medical devices, such as monitors and diagnostic equipment, utilize resistors for signal conditioning and power management. Precision and reliability are critical in these applications to ensure patient safety.

V. Trends in Resistor Technology

The resistor industry is continually evolving, with several trends shaping the future of resistor technology:

A. Advancements in Materials

New materials are being developed to enhance the performance of resistors. For example, the use of nanomaterials can improve stability and reduce size, leading to more efficient designs.

B. Miniaturization and Surface Mount Technology (SMT)

The trend towards miniaturization has led to the increased use of surface mount resistors. SMT allows for smaller, more compact designs, making it easier to integrate resistors into modern electronic devices.

C. Smart Resistors and IoT Integration

With the rise of the Internet of Things (IoT), smart resistors are being developed to provide real-time data and feedback. These resistors can adapt to changing conditions, enhancing the functionality of connected devices.

VI. Conclusion

A. Summary of Popular Resistor Types

In summary, resistors are essential components in electronic circuits, with various types available to suit different applications. Fixed resistors, variable resistors, and specialty resistors each serve unique purposes, contributing to the overall functionality of electronic devices.

B. Importance of Choosing the Right Resistor

Selecting the appropriate resistor type and specifications is crucial for ensuring the reliability and performance of electronic circuits. Understanding the characteristics of different resistors can help engineers and designers make informed decisions.

C. Future Outlook for Resistor Technology

As technology continues to advance, the resistor industry will likely see further innovations in materials, design, and functionality. The integration of smart technologies and the push for miniaturization will shape the future of resistors, making them even more versatile and essential in modern electronics.

VII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Electronic Materials

B. Industry Standards

- International Electrotechnical Commission (IEC) Standards

- American National Standards Institute (ANSI) Standards

C. Manufacturer Specifications

- Vishay Intertechnology

- Yageo Corporation

D. Online Resources and Databases

- Digi-Key Electronics

- Mouser Electronics

This comprehensive overview of popular resistor standard product types highlights their significance in electronic circuits and the importance of selecting the right components for various applications. As technology evolves, resistors will continue to play a vital role in the development of innovative electronic solutions.

Metal Resistor Product Training Precautions

I. Introduction

In the world of electronics, metal resistors play a crucial role in controlling the flow of electric current. These components are essential for a wide range of applications, from simple circuits to complex electronic devices. However, to ensure their effective use, proper training is paramount. This blog post will delve into the essential precautions and training requirements associated with metal resistors, providing a comprehensive guide for engineers, technicians, and quality control personnel.

II. Understanding Metal Resistors

A. What are Metal Resistors?

Metal resistors are passive electronic components that limit the flow of electric current in a circuit. They are typically made from a metal film or wire, which provides a stable and precise resistance value. There are various types of metal resistors, including metal film, metal oxide, and wire-wound resistors, each with unique characteristics suited for specific applications.

1. Composition and Types

Metal Film Resistors: Known for their accuracy and stability, these resistors are made by depositing a thin layer of metal onto a ceramic substrate.

Metal Oxide Resistors: These resistors are made from a metal oxide film and are known for their high-temperature stability and reliability.

Wire-Wound Resistors: Constructed by winding a metal wire around a core, these resistors can handle higher power ratings and are often used in high-performance applications.

2. Common Applications

Metal resistors are widely used in various applications, including:

- Voltage dividers

- Signal processing

- Current limiting

- Feedback circuits in amplifiers

B. Key Characteristics

Understanding the key characteristics of metal resistors is essential for their effective application.

1. Resistance Value

The resistance value, measured in ohms (Ω), determines how much current will flow through the resistor when a voltage is applied. Selecting the correct resistance value is critical for circuit functionality.

2. Tolerance

Tolerance indicates the precision of the resistor's resistance value. It is expressed as a percentage and signifies how much the actual resistance can vary from the stated value. For example, a 5% tolerance means the actual resistance can be 5% higher or lower than the specified value.

3. Temperature Coefficient

The temperature coefficient measures how much the resistance changes with temperature. A low temperature coefficient is desirable for applications requiring stable performance across varying temperatures.

4. Power Rating

The power rating indicates the maximum amount of power the resistor can dissipate without overheating. Exceeding this rating can lead to failure, making it crucial to select resistors with appropriate power ratings for specific applications.

III. Safety Precautions

A. General Safety Guidelines

Safety is paramount when working with metal resistors. Adhering to general safety guidelines can prevent accidents and ensure a safe working environment.

1. Personal Protective Equipment (PPE)

Always wear appropriate PPE, including safety glasses, gloves, and lab coats, to protect against potential hazards.

2. Electrical Safety

Ensure that all equipment is properly grounded and that you follow electrical safety protocols to prevent shocks or short circuits.

B. Handling Precautions

Proper handling of metal resistors is essential to maintain their integrity and performance.

1. Avoiding Physical Damage

Handle resistors with care to avoid physical damage. Dropping or mishandling can lead to micro-cracks or other defects that may affect performance.

2. Proper Storage Conditions

Store resistors in a controlled environment, away from extreme temperatures, humidity, and contaminants. Use anti-static bags or containers to prevent electrostatic discharge.

C. Environmental Considerations

The environment in which resistors are used can significantly impact their performance.

1. Temperature and Humidity Control

Maintain stable temperature and humidity levels to ensure optimal performance. Extreme conditions can lead to resistance drift or failure.

2. Avoiding Contaminants

Keep resistors away from dust, moisture, and chemicals that could compromise their performance.

IV. Training Requirements

A. Target Audience for Training

Training is essential for various personnel involved in the handling and application of metal resistors.

1. Engineers and Technicians

Engineers and technicians must understand the specifications, installation procedures, and testing techniques to ensure proper use.

2. Quality Control Personnel

Quality control personnel need training to assess the quality and performance of resistors, ensuring they meet industry standards.

B. Essential Training Topics

Training should cover several essential topics to equip personnel with the necessary knowledge.

1. Understanding Specifications

Personnel should be trained to interpret resistor specifications, including resistance values, tolerances, and power ratings.

2. Installation Procedures

Proper installation techniques, including soldering methods and mounting considerations, should be emphasized to prevent damage and ensure reliability.

3. Testing and Measurement Techniques

Training should include methods for testing and measuring resistor performance, such as using multimeters and oscilloscopes.

C. Certification and Compliance

Ensuring compliance with industry standards is crucial for maintaining quality and safety.

1. Industry Standards

Familiarize personnel with relevant industry standards, such as IEC and ANSI, to ensure compliance in manufacturing and testing.

2. Documentation and Record Keeping

Proper documentation and record-keeping practices should be established to track training, inspections, and compliance.

V. Installation Precautions

A. Pre-Installation Checks

Before installation, conducting thorough checks is essential to ensure compatibility and functionality.

1. Inspecting Components

Inspect all components for physical damage or defects before installation. This includes checking for proper labeling and specifications.

2. Verifying Compatibility

Ensure that the selected resistor is compatible with the circuit design and other components to prevent issues during operation.

B. Installation Techniques

Proper installation techniques are critical for ensuring the longevity and performance of metal resistors.

1. Soldering Methods

Use appropriate soldering techniques to avoid overheating the resistor, which can lead to damage. Consider using low-temperature solder for sensitive components.

2. Mounting Considerations

Ensure that resistors are mounted securely and in a manner that allows for proper heat dissipation. Avoid placing them near heat sources or in enclosed spaces without ventilation.

C. Post-Installation Testing

After installation, conducting thorough testing is essential to verify functionality.

1. Functional Testing

Perform functional tests to ensure that the resistor is operating within its specified parameters. This may include measuring voltage and current levels.

2. Troubleshooting Common Issues

Be prepared to troubleshoot common issues, such as overheating or resistance drift, and take corrective actions as necessary.

VI. Maintenance and Monitoring

A. Regular Inspection Protocols

Regular inspections are vital for maintaining the performance of metal resistors.

1. Visual Checks

Conduct visual inspections to identify any signs of wear, damage, or contamination.

2. Performance Monitoring

Monitor the performance of resistors over time to detect any changes in resistance or functionality.

B. Identifying Signs of Wear or Failure

Recognizing signs of wear or failure can prevent catastrophic failures.

1. Heat Damage

Look for discoloration or deformation, which may indicate overheating.

2. Resistance Drift

Monitor for changes in resistance values, which can signal potential failure.

C. Replacement Guidelines

Knowing when and how to replace resistors is crucial for maintaining circuit integrity.

1. When to Replace

Replace resistors that show signs of damage, wear, or performance issues to prevent circuit failure.

2. Disposal of Old Resistors

Follow proper disposal guidelines for old resistors, considering environmental regulations and safety protocols.

VII. Conclusion

In conclusion, understanding the precautions and training requirements associated with metal resistors is essential for ensuring their effective use in electronic applications. By adhering to safety guidelines, conducting thorough training, and implementing proper installation and maintenance practices, personnel can enhance the reliability and performance of metal resistors. Ongoing education and adherence to best practices will contribute to a safer and more efficient working environment.

VIII. References

- Industry Standards and Guidelines

- Recommended Reading and Resources

- Contact Information for Further Training and Support

By following these guidelines and investing in proper training, organizations can ensure that their personnel are well-equipped to handle metal resistors safely and effectively, ultimately leading to improved product quality and performance.

What are the Popular Porcelain Tube Resistor Product Types? I. IntroductionPorcelain tube resistors are essential components in various electronic circuits, providing resistance to the flow of electric current. These resistors are made from a combination of porcelain and conductive materials, offering unique properties that make them suitable for high-temperature and high-voltage applications. In this article, we will explore the different types of porcelain tube resistors, their characteristics, applications, and factors to consider when selecting the right type for your needs. II. Understanding Porcelain Tube Resistors A. Composition and ConstructionPorcelain tube resistors are primarily composed of a ceramic material known as porcelain, which is known for its excellent electrical insulation properties and high-temperature resistance. The manufacturing process involves shaping the porcelain into tubes and then applying a resistive material, typically a metal or metal oxide, to the surface. This combination results in a durable and reliable resistor that can withstand harsh environmental conditions. B. Characteristics and Advantages1. **High-Temperature Resistance**: Porcelain tube resistors can operate effectively at elevated temperatures, making them ideal for applications where heat dissipation is a concern. 2. **Electrical Insulation Properties**: The porcelain material provides excellent insulation, preventing electrical leakage and ensuring safety in high-voltage applications.3. **Durability and Longevity**: These resistors are resistant to mechanical stress and environmental factors, contributing to their long lifespan and reliability in various applications. C. Applications in Various IndustriesPorcelain tube resistors find applications across multiple industries, including:1. **Electronics**: Used in power supplies, amplifiers, and other electronic devices where precise resistance is required. 2. **Automotive**: Employed in automotive electronics, such as ignition systems and control units, where high reliability is crucial.3. **Industrial Machinery**: Utilized in heavy machinery and equipment that require robust components capable of withstanding harsh operating conditions. III. Popular Types of Porcelain Tube Resistors A. Fixed Porcelain Tube Resistors1. **Description and Features**: Fixed porcelain tube resistors have a predetermined resistance value that does not change. They are available in various resistance ratings and power levels.2. **Common Applications**: These resistors are widely used in circuits where a stable resistance is required, such as in voltage dividers and current limiting applications.3. **Advantages and Limitations**: The main advantage of fixed resistors is their simplicity and reliability. However, they lack the flexibility of variable resistors, making them unsuitable for applications requiring adjustable resistance. B. Variable Porcelain Tube Resistors1. **Description and Features**: Variable porcelain tube resistors, also known as potentiometers, allow users to adjust the resistance value. They typically have a rotating or sliding mechanism for easy adjustment.2. **Common Applications**: These resistors are commonly used in audio equipment, dimmer switches, and other applications where variable resistance is needed.3. **Advantages and Limitations**: The primary advantage of variable resistors is their versatility. However, they may be less durable than fixed resistors and can be more susceptible to wear over time. C. Wirewound Porcelain Tube Resistors1. **Description and Features**: Wirewound porcelain tube resistors consist of a wire coil wrapped around a porcelain tube. This design allows for precise resistance values and high power ratings.2. **Common Applications**: They are often used in high-power applications, such as power amplifiers and industrial equipment.3. **Advantages and Limitations**: Wirewound resistors offer excellent stability and accuracy. However, they may have a higher inductance compared to other types, which can affect performance in high-frequency applications. D. High-Power Porcelain Tube Resistors1. **Description and Features**: High-power porcelain tube resistors are designed to handle significant power loads, making them suitable for demanding applications.2. **Common Applications**: These resistors are commonly found in power electronics, such as inverters and motor drives.3. **Advantages and Limitations**: The main advantage is their ability to dissipate heat effectively. However, they may be bulkier and more expensive than standard resistors. E. Specialty Porcelain Tube Resistors1. **Description and Features**: Specialty porcelain tube resistors are designed for specific applications, such as high-voltage or high-frequency environments.2. **Common Applications**: These resistors are used in telecommunications, aerospace, and other specialized fields.3. **Advantages and Limitations**: Specialty resistors offer tailored solutions for unique challenges. However, they may not be as widely available and can be more costly. IV. Comparison of Porcelain Tube Resistor Types A. Performance Metrics1. **Resistance Range**: Different types of porcelain tube resistors offer varying resistance ranges, with fixed resistors providing specific values and variable resistors allowing for adjustments.2. **Power Rating**: High-power resistors are designed to handle more significant loads, while standard fixed and variable resistors may have lower power ratings.3. **Temperature Coefficient**: The temperature coefficient indicates how resistance changes with temperature. Wirewound and specialty resistors often have lower temperature coefficients, providing better stability. B. Cost ConsiderationsThe cost of porcelain tube resistors can vary significantly based on type, power rating, and manufacturer. Fixed resistors are generally more affordable, while high-power and specialty resistors tend to be more expensive due to their advanced features and materials. C. Suitability for Specific ApplicationsWhen selecting a porcelain tube resistor, it is essential to consider the specific requirements of your application. For example, high-power applications may necessitate the use of high-power resistors, while audio equipment may benefit from variable resistors for fine-tuning. V. Factors to Consider When Choosing Porcelain Tube Resistors A. Application RequirementsUnderstanding the specific needs of your application is crucial. Consider factors such as resistance value, power rating, and whether you need a fixed or variable resistor. B. Environmental ConditionsEvaluate the environmental conditions in which the resistor will operate. High-temperature or high-humidity environments may require resistors with enhanced durability and insulation properties. C. Electrical SpecificationsEnsure that the resistor meets the electrical specifications of your circuit, including voltage ratings and tolerance levels. D. Manufacturer Reputation and Quality AssuranceChoose resistors from reputable manufacturers known for their quality assurance processes. This can help ensure reliability and performance in your applications. VI. ConclusionPorcelain tube resistors play a vital role in electronic circuits, offering unique characteristics that make them suitable for various applications. From fixed and variable types to high-power and specialty resistors, each type has its advantages and limitations. When selecting the right porcelain tube resistor, it is essential to consider application requirements, environmental conditions, and electrical specifications. By understanding the different types available and their respective features, you can make informed decisions that enhance the performance and reliability of your electronic systems. VII. ReferencesA. List of sources for further reading B. Suggested manufacturers and suppliers of porcelain tube resistorsIn conclusion, porcelain tube resistors are indispensable components in modern electronics, and understanding their types and characteristics can significantly impact the success of your projects. Whether you are designing a new circuit or upgrading existing equipment, the right porcelain tube resistor can make all the difference.

Understanding Resistor Resistance I. IntroductionIn the world of electronics, understanding the fundamental concepts of electricity is crucial for anyone looking to design, build, or repair electronic devices. One of the key components in electrical circuits is the resistor, which plays a vital role in controlling the flow of electric current. This article aims to provide a comprehensive understanding of resistor resistance, its significance, and its applications in various electronic devices. II. Basic Concepts of ElectricityTo grasp the concept of resistor resistance, it is essential to first understand the basic principles of electricity. A. Overview of Electrical Current, Voltage, and Resistance1. **Definition of Electrical Current**: Electrical current is the flow of electric charge, typically measured in amperes (A). It represents the movement of electrons through a conductor, such as a wire.2. **Definition of Voltage**: Voltage, or electric potential difference, is the force that pushes electric current through a circuit. It is measured in volts (V) and can be thought of as the pressure that drives the flow of electrons.3. **Definition of Resistance**: Resistance is the opposition to the flow of electric current. It is measured in ohms (Ω) and determines how much current will flow for a given voltage. Higher resistance means less current will flow, while lower resistance allows more current to pass through. B. Ohm's LawOhm's Law is a fundamental principle in electronics that describes the relationship between voltage, current, and resistance. 1. **Explanation of the Relationship**: According to Ohm's Law, the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor.2. **Mathematical Representation**: The relationship is mathematically represented as: \[ V = I \times R \] This equation allows us to calculate any one of the three variables if the other two are known. III. What is a Resistor? A. Definition and Function of a ResistorA resistor is a passive electronic component that resists the flow of electric current. Its primary function is to limit current, divide voltages, and dissipate energy in the form of heat. Resistors are essential in controlling the behavior of electrical circuits. B. Types of Resistors1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in circuits where a specific resistance is required.2. **Variable Resistors**: These include potentiometers and rheostats, which allow users to adjust the resistance value. They are often used in applications like volume controls and dimmer switches.3. **Specialty Resistors**: These include thermistors (temperature-sensitive resistors) and photoresistors (light-sensitive resistors), which change resistance based on environmental conditions. C. Physical Construction of Resistors1. **Materials Used**: Resistors can be made from various materials, including carbon, metal film, and wire-wound constructions. Each material has its own characteristics, affecting the resistor's performance.2. **Size and Shape Variations**: Resistors come in different sizes and shapes, from small surface-mount devices to larger through-hole components, allowing for versatility in circuit design. IV. Measuring Resistance A. Tools for Measuring Resistance1. **Multimeter**: A multimeter is a versatile tool that can measure voltage, current, and resistance. It is essential for troubleshooting and testing electronic circuits.2. **Ohmmeter**: An ohmmeter is a specialized device used solely for measuring resistance. It provides a direct reading of resistance values. B. Understanding Resistance Values1. **Color Coding System for Resistors**: Resistors are often marked with colored bands that indicate their resistance value and tolerance. Each color corresponds to a specific number, allowing users to decode the resistor's specifications.2. **Reading and Interpreting Resistor Values**: By understanding the color coding system, users can easily determine the resistance value of a resistor and ensure it meets the requirements of their circuit. V. Factors Affecting Resistance A. Material Properties1. **Conductivity and Resistivity**: Different materials have varying levels of conductivity and resistivity, which directly affect their resistance. Conductors like copper have low resistance, while insulators like rubber have high resistance.2. **Temperature Effects on Resistance**: The resistance of most materials changes with temperature. For example, as temperature increases, the resistance of a conductor typically increases, while that of a thermistor may decrease. B. Physical Dimensions of Resistors1. **Length, Cross-Sectional Area, and Resistance**: The resistance of a resistor is influenced by its physical dimensions. Longer resistors have higher resistance, while those with a larger cross-sectional area have lower resistance. C. Environmental Factors1. **Influence of Humidity and Temperature on Resistance**: Environmental conditions can affect the performance of resistors. High humidity can lead to corrosion, while extreme temperatures can alter resistance values. VI. Applications of ResistorsResistors are used in a wide range of applications, including: A. Current LimitingResistors are often used to limit the amount of current flowing through a circuit, protecting sensitive components from damage. B. Voltage DivisionIn voltage divider circuits, resistors are used to create specific voltage levels, allowing for the proper functioning of various electronic devices. C. Signal ConditioningResistors play a crucial role in signal conditioning, helping to filter and shape electrical signals for processing. D. Thermal ManagementIn some applications, resistors are used to dissipate heat, ensuring that electronic components operate within safe temperature ranges. E. Examples of Resistors in Everyday Electronic DevicesResistors are found in virtually all electronic devices, from smartphones and computers to household appliances and automotive systems. VII. Common Misconceptions about Resistors A. Resistance as a Measure of Energy LossMany people mistakenly believe that resistance is solely a measure of energy loss. While resistors do dissipate energy as heat, they also serve essential functions in controlling current and voltage. B. The Role of Resistors in Circuit DesignSome may underestimate the importance of resistors in circuit design. They are critical for ensuring that circuits operate correctly and efficiently. C. Misunderstanding Resistor Ratings and TolerancesResistor ratings and tolerances can be confusing. Understanding these specifications is vital for selecting the right resistor for a given application. VIII. ConclusionUnderstanding resistor resistance is fundamental for anyone interested in electronics. Resistors play a crucial role in controlling current, dividing voltages, and ensuring the proper functioning of electronic devices. By grasping the concepts outlined in this article, readers can gain a deeper appreciation for the importance of resistors in modern technology.As you continue your journey into the world of electronics, consider exploring further into circuit design and the various components that make up electronic systems. Resistors may seem simple, but their impact on technology is profound and far-reaching. IX. ReferencesFor those interested in further learning, consider the following resources:- "The Art of Electronics" by Paul Horowitz and Winfield Hill- Online platforms like Khan Academy and Coursera for courses on electronics- Tools like Digi-Key and Mouser for resistor values and circuit design calculatorsBy delving into these resources, you can enhance your understanding of resistors and their critical role in the world of electronics.

The Latest Resistor Specifications I. IntroductionResistors are fundamental components in electrical and electronic circuits, serving the essential function of controlling current flow. They are ubiquitous in various applications, from simple household devices to complex industrial machinery. Understanding the specifications of resistors is crucial for engineers, designers, and hobbyists alike, as these specifications dictate how a resistor will perform in a given application. This blog post aims to provide an in-depth look at the latest resistor specifications, exploring recent developments in technology, detailed specifications, and practical applications. II. Understanding Resistor Basics A. What is a Resistor?A resistor is a passive electrical component that opposes the flow of electric current, resulting in a voltage drop across its terminals. This property is quantified by the resistance value, measured in ohms (Ω). Resistors are essential for controlling current levels, dividing voltages, and protecting sensitive components from excessive current. 1. Function in Electrical CircuitsIn electrical circuits, resistors serve multiple purposes, including current limiting, voltage division, and signal conditioning. They are used in various configurations, such as series and parallel arrangements, to achieve desired electrical characteristics. 2. Types of ResistorsResistors come in various types, including fixed, variable, and specialty resistors. Fixed resistors have a constant resistance value, while variable resistors, such as potentiometers, allow for adjustable resistance. Specialty resistors, like thermistors and photoresistors, change resistance based on temperature or light exposure. B. Key Parameters of ResistorsWhen selecting a resistor, several key parameters must be considered: 1. Resistance ValueThe resistance value is the primary specification of a resistor, determining how much it opposes current flow. Standard values are often defined by the E12 and E24 series, which provide a range of preferred numbers. 2. ToleranceTolerance indicates the precision of the resistance value, expressed as a percentage. A resistor with a tolerance of ±5% can have a resistance value that varies by 5% from its nominal value. 3. Power RatingThe power rating, measured in watts (W), indicates the maximum power a resistor can dissipate without overheating. Exceeding this rating can lead to failure or damage. 4. Temperature CoefficientThe temperature coefficient measures how much a resistor's resistance changes with temperature, typically expressed in parts per million per degree Celsius (ppm/°C). A lower temperature coefficient indicates better stability across temperature variations. III. Recent Developments in Resistor Technology A. Advances in MaterialsRecent advancements in materials have significantly improved resistor performance. 1. Carbon Film ResistorsCarbon film resistors are known for their stability and low noise characteristics. They are widely used in applications requiring reliable performance. 2. Metal Film ResistorsMetal film resistors offer superior precision and lower temperature coefficients compared to carbon film resistors. They are ideal for applications demanding high accuracy. 3. Wirewound ResistorsWirewound resistors are constructed by winding a wire around a core. They can handle high power ratings and are often used in high-performance applications. B. Innovations in DesignThe design of resistors has also evolved, with innovations such as: 1. Surface Mount Technology (SMT)SMT resistors are compact and suitable for automated assembly processes. Their small size allows for higher circuit density, making them popular in modern electronics. 2. Thin Film vs. Thick Film ResistorsThin film resistors offer better performance in terms of tolerance and temperature coefficient, while thick film resistors are more cost-effective for general applications. C. Enhanced Performance FeaturesRecent developments have led to enhanced performance features in resistors, including: 1. Improved Tolerance LevelsManufacturers are now producing resistors with tighter tolerances, such as 0.1% and 0.5%, catering to applications that require high precision. 2. Higher Power RatingsAdvancements in materials and design have enabled the production of resistors with higher power ratings, allowing them to handle more demanding applications. 3. Miniaturization TrendsThe trend towards miniaturization in electronics has led to the development of smaller resistors without compromising performance, making them suitable for compact devices. IV. Detailed Specifications of Latest Resistors A. Resistance Range 1. Standard ValuesThe latest resistors are available in a wide range of standard values, typically following the E12, E24, and E96 series. These series provide a systematic approach to selecting resistance values. 2. Custom ValuesFor specialized applications, manufacturers often offer custom resistance values, allowing designers to meet specific circuit requirements. B. Tolerance Levels 1. Standard Tolerances (1%, 5%, etc.)Standard resistors typically come with tolerances of 1% or 5%, suitable for most general applications. 2. Precision Resistors (0.1%, 0.5%)Precision resistors are available with tolerances as low as 0.1% or 0.5%, making them ideal for high-accuracy applications such as instrumentation and measurement. C. Power Ratings 1. Common Power Ratings (1/8W, 1/4W, etc.)Common power ratings for resistors include 1/8W, 1/4W, and 1/2W, suitable for low to moderate power applications. 2. High-Power ResistorsHigh-power resistors, rated for several watts or even kilowatts, are designed for applications requiring significant power dissipation, such as power supplies and motor control circuits. D. Temperature Coefficient 1. Importance of Temperature StabilityTemperature stability is crucial for maintaining consistent performance in varying environmental conditions. Resistors with low temperature coefficients are preferred in precision applications. 2. Typical Values for Different TypesTypical temperature coefficients vary by resistor type, with metal film resistors often exhibiting coefficients as low as ±10 ppm/°C, while carbon film resistors may have coefficients around ±100 ppm/°C. V. Applications of Latest Resistor SpecificationsThe latest resistor specifications find applications across various industries: A. Consumer ElectronicsIn consumer electronics, resistors are used in devices such as smartphones, televisions, and audio equipment, where reliability and performance are paramount. B. Automotive IndustryThe automotive industry relies on resistors for various functions, including sensor applications, power management, and control systems, where high precision and durability are essential. C. Industrial AutomationIn industrial automation, resistors play a critical role in control systems, signal processing, and power distribution, ensuring efficient operation of machinery and equipment. D. TelecommunicationsTelecommunications equipment utilizes resistors for signal conditioning, impedance matching, and circuit protection, where performance and reliability are crucial. E. Medical DevicesIn medical devices, precision resistors are vital for accurate measurements and reliable operation, ensuring patient safety and effective diagnostics. VI. Selecting the Right Resistor A. Factors to ConsiderWhen selecting a resistor, several factors must be considered: 1. Application RequirementsUnderstanding the specific requirements of the application, including resistance value, power rating, and tolerance, is essential for choosing the right resistor. 2. Environmental ConditionsEnvironmental factors, such as temperature and humidity, can affect resistor performance. Selecting resistors with appropriate temperature coefficients and ratings is crucial for reliability. B. Guidelines for Choosing Resistors 1. Matching Specifications to NeedsIt is important to match resistor specifications to the needs of the application, ensuring optimal performance and reliability. 2. Importance of Quality and ReliabilityChoosing high-quality resistors from reputable manufacturers can significantly impact the overall performance and longevity of the circuit. VII. ConclusionIn summary, understanding the latest resistor specifications is essential for anyone involved in electrical and electronic design. With advancements in materials, design, and performance features, resistors have become more versatile and reliable than ever. As technology continues to evolve, staying updated with the latest specifications will be crucial for ensuring optimal performance in various applications. The future of resistor technology promises even more innovations, paving the way for enhanced performance and efficiency in electronic circuits. VIII. References- Academic Journals on Electrical Engineering- Industry Standards from the International Electrotechnical Commission (IEC)- Manufacturer Specifications and Datasheets from leading resistor manufacturersThis comprehensive overview of the latest resistor specifications provides valuable insights for engineers, designers, and enthusiasts, ensuring they are well-equipped to make informed decisions in their projects.